TBM21E, TBM25S & TBM4BB SHURE STAKE® TOOL CALIBRATION VERIFICATION TA01342 E Page 1 of 2 WARNING HANDLES ARE NON-INSULATING. DO NOT CRIMP ON HOT ENERGIZED WIRES. To release the SHURE STAKE® mechanism, push up on the release bar until the ratchet teeth are disengaged. WARNING KEEP ALL BODY PARTS AWAY FROM DIE NEST DURING GAGING OR CRIMPING ...

TBM21E / TBM25S / TBM4BB SHURE STAKE® TOOL For Installing Color-Keyed® Copper & Alumunum Lugs and Splices, C-Taps and Pigtails In the event the SHURE STAKE® MECHANISM must be released, please see Figure 4. TA01299 E Page 1 of 2 1. Open handles fully. 2. Depress wheel release button and rotate wheel to proper die nest. Allow wheel to lock ...

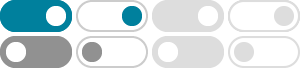

TBM25S Crimp tool with Shure-Stake® mechanism for #8–#2 copper and #10–#6 aluminum 1 TBM25S Crimp Tool • Wide range of #8 to #2 for copper lugs and #10 to #6 for aluminum lugs • Each die has die code embossing • Shure-Stake® mechanism ensures a properly completed crimp each time • Color-coded die wheel rotates into position for ...

3.0 3.3 GAGING PROCEDURE CALIBRATION VERIFICATION NOTE: Calibration verification of the tool should be performed whenever damage or suspected damage has occurred or as often as operating conditions warrant. TA00084 G Page 5 of 6 3.1 VISUAL INSPECTION 1. Tool must be free of cracks, sharp edges and

BLUE GREY RED BROWN Push to Release Die Wheel Green Die C-TAPS ONLY Model No. Featuring the Color-Keyed® System TBM45S COMFORT CRIMP® COMPRESSION TOOL WITH SHURE STAKE® MECHANISM For Installing Color-Keyed® Copper and Aluminum Lugs, Splices, C-Taps and Pigtails 8-2 AWG Cu, 10-6 AWG Al

tbm21e, tbm25s tbm41e, tbm45s tbm5 tbm6 13642m tbm12 13100a, tbm14rh tbm15i tbm8-750m-1 tbm8-750 die crimps die crimps upper die lower die crimps die crimps die crimps die crimps crimps 54104bs rotating die 2 13454 1 13475 13477 1 11732 1 tbm12d-1 1 15520 1 1 7/16"

tbm25s tbm21e tbm45s tbm41e ** tbm4s tbm5 tbm6 tbm8 tbm6h 6 ton 12 ton 14 / 15 ton 40 ton bplt6bscr bplt62bscr bpi42cr bplt14bscr bplt15bscr hs12-6 ac4x3 54104 54130 we-54130 54131 541322 54204 7/16 8 str 23 navy 8 weld 37/24 red 21 #8 g, h, k tbm62x tbm6221x 15500x 15520x 2 1 1 1 1 1 1 1 1 1 1 1 54134 54105 54135 54136 54205 6 str 30 navy 6 ...

2.0 2.1 INSTALLATION TEST PROCEDURE INSTALLATION TEST PROCEDURE (TBM8S ONLY) WARNING SHURE STAKE® SAFETY RELEASE The TBM8S compression tool is equipped with the Shure Stake® full stroke compelling mechanism. If it becomes necessary to release the Shure Stake® Mechanism before completion of the crimp cycle, disengage ratchet as follows. Slightly squeeze ...

- [PDF]

Overview - tnb.com

5.2 323 Overview FEATURES BENEFITS High conductivity electrolytic copper Excellent electrical conductivity thanks to lowest electrical resistance, associated to superior tensile strength

2.0 2.1 INSTALLATION TEST PROCEDURE INSTALLATION TEST PROCEDURE (TBM6S ONLY) TA01977 E Page 4 of 6 CAUTION Care should be taken to strip the insulation of the conductor without cutting or nicking the conductor strands, as this